Coin Plating Barrels

Eagle Engineering is vastly experienced in designing, manufacturing and installing coin plating barrels for renowned coin manufacturers in the UK, Europe and throughout the world.

Coin entrapment and part-plating or over-plating cause extra cost through production delays and wastage. Our customers report zero defects in their coin plating process – which reduces operating costs and enables faster coin plating. We understand the stringent requirements of coin plating processes and help our clients to achieve production efficiency and consistency.

Coin Plating Barrels

Eagle Engineering is vastly experienced in designing, manufacturing and installing coin plating barrels for renowned coin manufacturers in the UK, Europe and throughout the world.

Coin entrapment and part-plating or over-plating cause extra cost through production delays and wastage. Our customers report zero defects in their coin plating process – which reduces operating costs and enables faster coin plating. We understand the stringent requirements of coin plating processes and help our clients to achieve production efficiency and consistency.

High Capacity Coin Plating Equipment Features

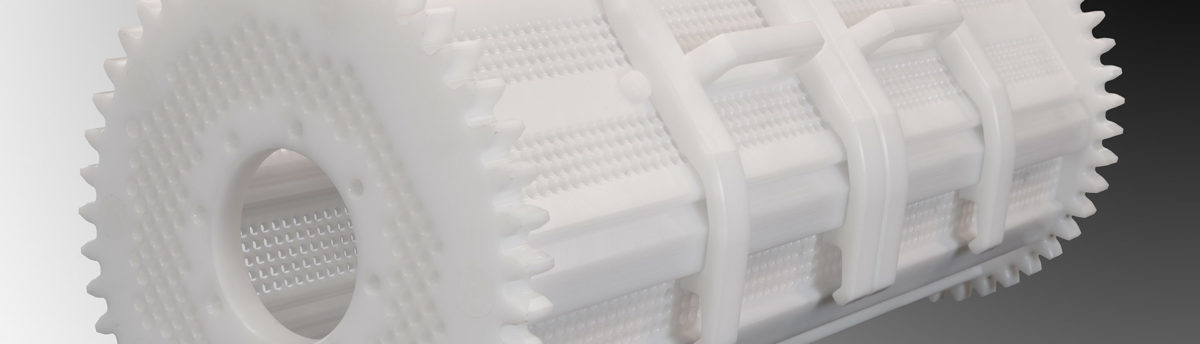

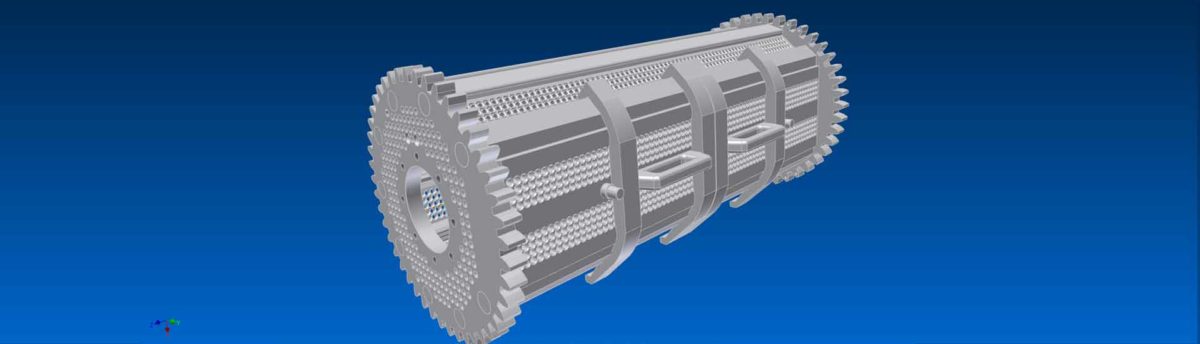

- Multi-coin barrel configuration option for mass coin plating operation with a total load capacity in excess of 480kg

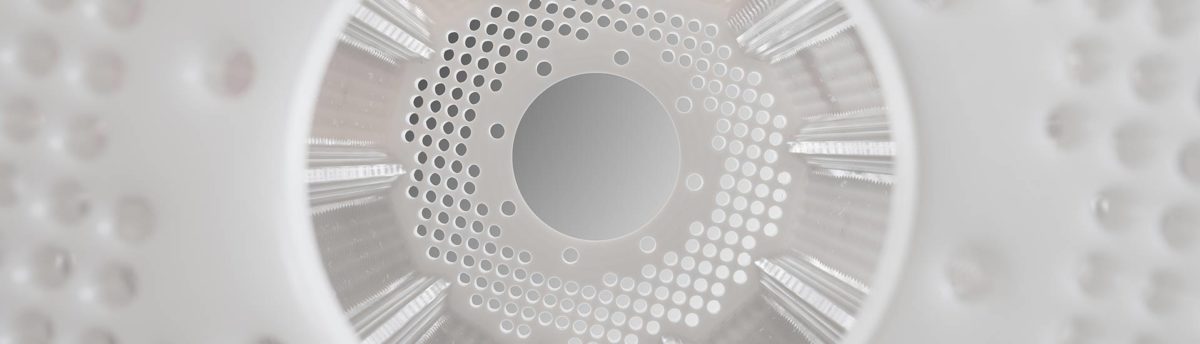

- The unique Eagle sinusoidal barrel lid specifically designed for the plating of coins to eradicate entrapment

- The internal faces of the coin plating barrel are CNC machined to our unique design, achieving a remarkable open area of over 40%, for maximum electrolytic transfer

- Each perforation has a nodular form to prevent coin adhesion, resulting in outstanding plating performance

- All holes are externally chamfered to assist electrolytic solution transfer. This provides the opportunity to increase the amps and reduce the volts into the barrel to improve plating efficiency and save money in the plating process

- The wear characteristics of U.H.M.W PE 1000 ensure hole integrity is maintained even after several years of service (see our test results)

See more information about plating barrels

Please call us or complete our Contact Form